Production Lines

Our tailor made conveyor belt production lines are recommended to our customers who are dealing with the production of small or medium-sized products. Our production lines are manufactured in a variety of sizes to suit the customer’s needs and the product to be manufactured. The material and design of the conveyor belt are selected depending on the product and the machining process. In order to speed up the processes, we also create multi-tier transport tracks in combination with lift systems. It is possible to use individual manufacturer / product trays, which reduces the error percentage and the time needed to produce the product. Dosing of raw materials / semi-finished products, filtering and removing scraps and packaging the finished products can be solved by manual or fully automated / robotic solutions.

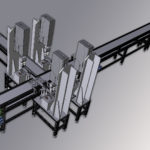

Our uniquely designed base station production lines are recommended to our customers who manufacture large-scale and non-mass production / serial products. Unlike belt systems, the universal base stations are built according to the steps of the production process. The base stations have their own electrical, pneumatic and network connections and contain all the necessary systems for operation. The stations can be controlled individually (manually) and centrally. Base stations can be equipped with an individual platte / motherboard according to the current product / production. The platform is quick and easy to replace, making it easier to switch to other products. The semi-finished products can be transported between base stations on a pre-installed rail system and on custom-designed trolleys, for which product-specific fixing frames can be placed.

In order to facilitate production processes and increase efficiency, it is possible to develop stand-alone machines / tools and cells for individual processes / tasks along the production lines. From special hand tools to automated robot cells, we can offer solutions to our customers when it comes to performing additional tasks that cannot be integrated into the production line or complement the existing production line.

- Manipulator arms

- Robot arms

- Camera monitoring systems

(Keyence, Omron, Cognex, Banner…) - Sensory control systems

(laser, optical, inductive, capacitive) - Traceability systems

(integrating to an existing or new system)